eHydroCOM – Electric Stepless Capacity Control System

Achieve precise and fast process control while saving energy

Solve stepless control tasks precise and fast

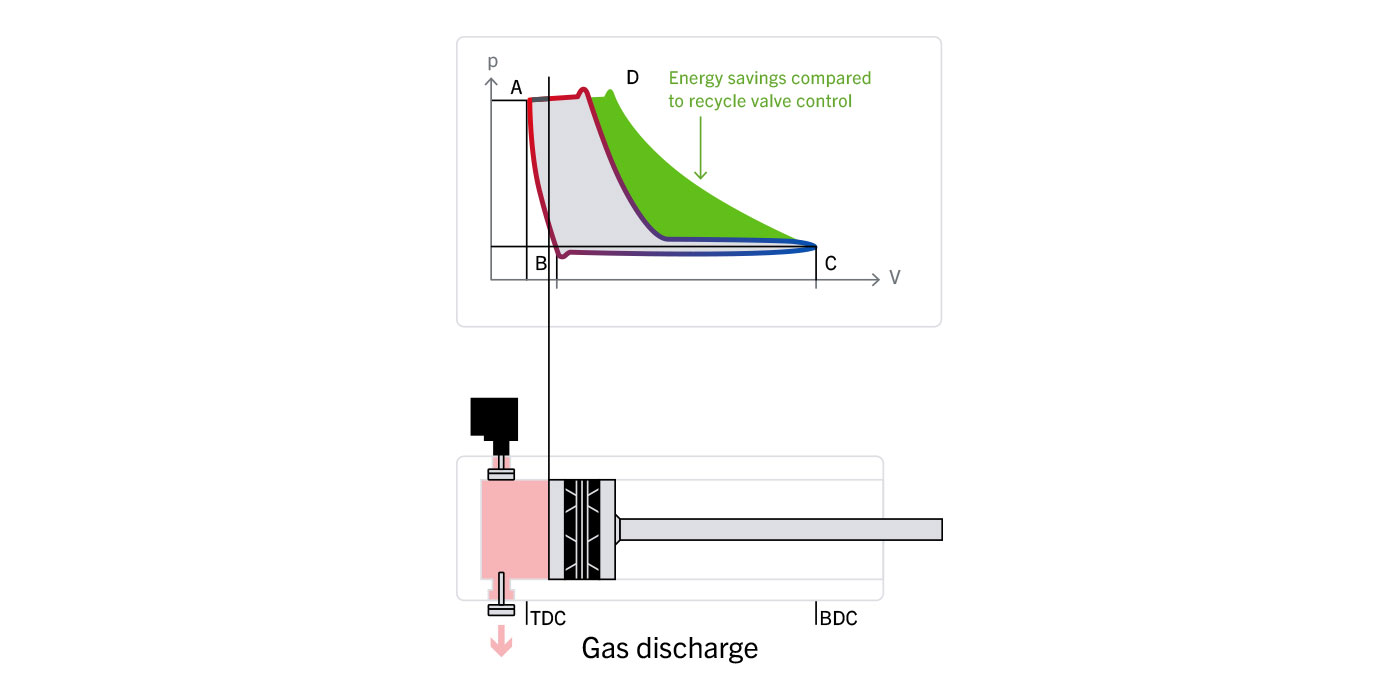

Many reciprocating compressors need to deliver less than their rated capacity, and this typically requires excess compressed gas to be returned to the suction side via a recycle valve. When this happens, the energy used to compress this recycled gas is wasted. HOERBIGER’s eHydroCOM is an all-electric stepless volume control system available today for reciprocating compressors. The fully standardized, 100% oil-free system is the ideal way to achieve and maintain stable capacity control of dynamic processes.

Precise capacity control

eHydroCOM continuously adjusts the compressor’s delivery rate to match the amount required by the downstream process. Precise control of the suction valves eliminates the need for a bypass valve. This not only saves energy and reduces CO2 emissions, but also improves your process controls at the same time.

Conventional capacity control systems waste energy because they either require gas to be compressed unnecessarily (bypass valves) or cannot accurately match the required flow rate (stepwise capacity control, which is also time-consuming to adjust). eHydroCOM, in contrast, offers a wide and stepless control range, from below 10% (depending on the application) up to 100%. Delivery rate can be adjusted continuously and automatically, with no time lag. Together with the wide turndown, this means you can operate your compressors more flexibly, cover your needs with a smaller fleet, react quickly and avoid overcapacity issues.

Test your energy savings here.

The best solution for your challenges

Standardized and ready for use immediately

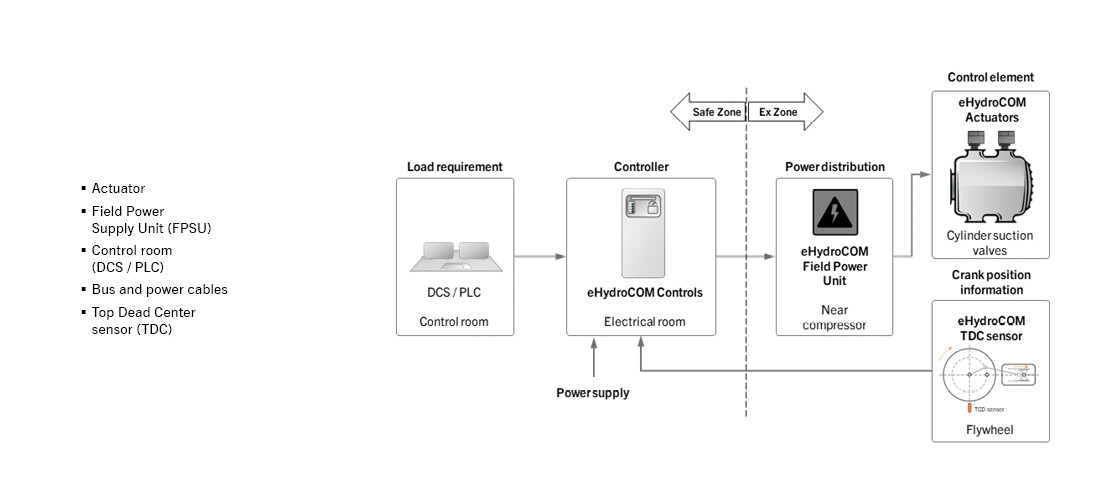

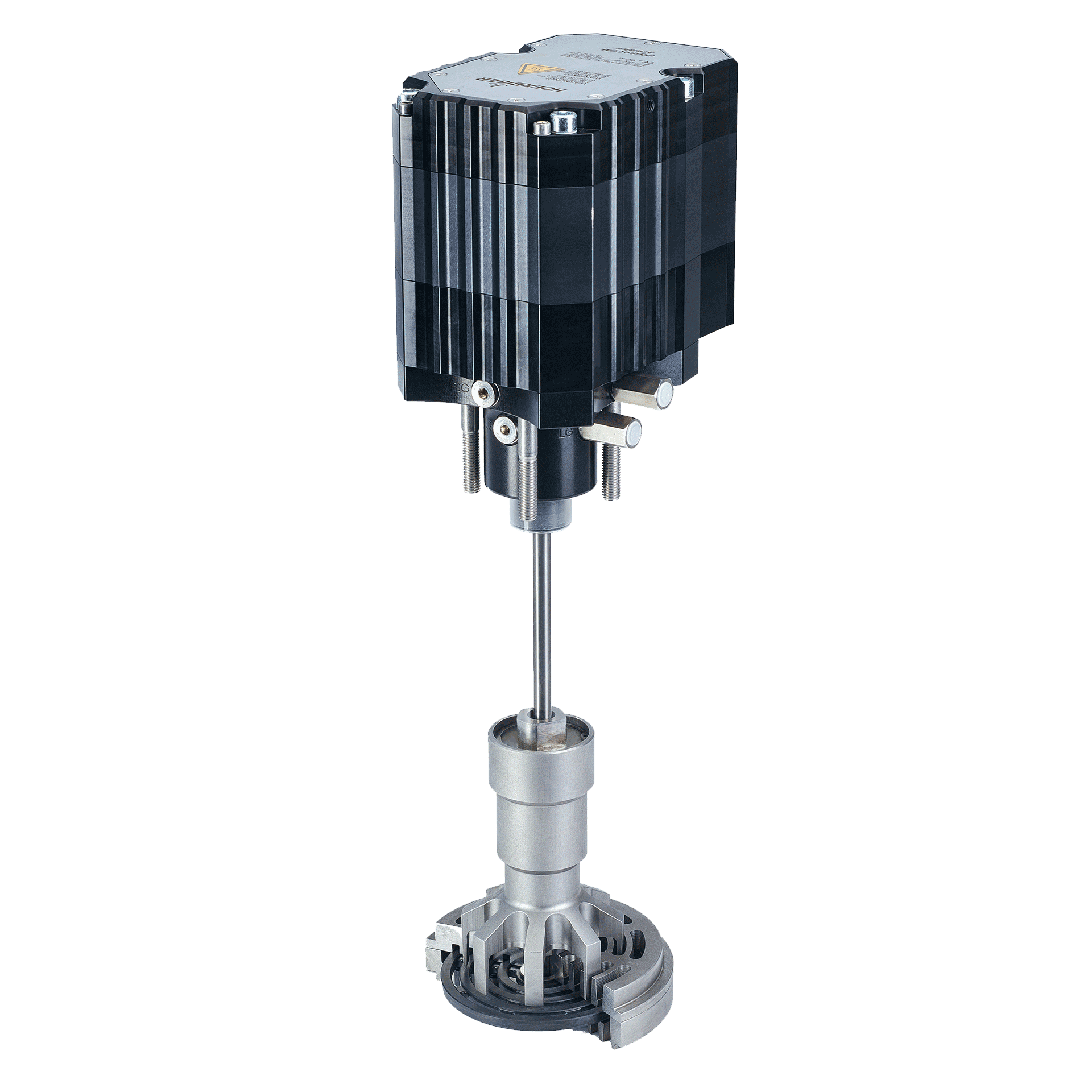

The patented eHydroCOM actuator is a smart device that combines a range of electronic and electric drive technologies to increase the reliability, efficiency and lifetime of your compressor. With no hydraulic oil to leak, and a design that is almost wear-free in operation, eHydroCOM reduces potential points of failure and keeps downtime to a minimum.

Failure prevention through real-time monitoring of the actuator

Digital networking capabilities allow you to monitor your actuator in real time and thus detect failures early – or even avoid them altogether. And, thanks to our remote maintenance system, any problems that do arise can be quickly assessed by HOERBIGER experts if necessary. If spare parts are required, HOERBIGER always has semi-finished products ready, reducing or eliminating the need for you to carry spares.

Reduced operating costs with eHydroCOM

Taking advantage of plug-and-play connections, eHydroCOM XD – our most powerful and compact system for extreme duties – can be easily retrofitted to your existing compressors with minimal downtime. The self-calibration feature means that even untrained personnel with less experience can install and commission eHydroCOM. In line with the motto “one size fits all”, it’s easy to replace the actuators. For you this means less inventory and less downtime. Your compressor is ready for use again immediately after maintenance.

With eHydroCOM, our employees – even those without years of operating experience – are able to start and stop the compressors. Thanks to the significantly more robust controls, pressure fluctuations in the hydrogen systems are almost imperceptible, and so we avoid unplanned downtime. The support through remote maintenance works perfectly.

„Your benefits at a glance

| Feature | Advantage | Benefit |

|---|---|---|

| Reverse flow control: The delivery rate of the compressor adjusts continuously to process requirements | No need for energy-wasting bypass valves | Saves energy while improving process control Reduces OPEX and CO2 emissions (Scope 1 or 2) |

| Reverse flow control: Wider control range, and ability to assign new duties to individual compressors | Flexibility in the compressor fleet and increased versatility, allowing precise and fast control of flow and pressure | Prevents overcapacity due to smaller fleet and fast response to changes |

| System architecture allows highest standardization: “One size fits all” | Simple and quick maintenance, repair, and asset management | Increases compressor availability and improves reliability due to long mean time between maintenance (MTBM) and short mean time to repair (MTTR) Reduces the risk of lost production (LPO) |

| 100% oil-free and all-electric operating principle | Capacity control easier than ever before Simple and quick installation, commissioning, and maintenance | Lower total cost of ownership (TCO) and better economics (ROI) due to obsolete hydraulics and lower lifetime costs at competitive investment (CAPEX) |

| Fully digitalized system design and real-time monitoring of the actuator | All data at your fingertips, allowing valuable insights and enabling quick diagnosis | Increases availability due to instant access to all relevant data via webUI* or GUI, also remotely, if preferred |

| * only available for eHydroCOM HD |

Working principle of eHydroCOM

Electric Stepless Capacity Control System

Heavy Duty Single Stack Actuator

- Actuator layout:

- Single magnetic coil stack

- Application limits:

- Up to 2.5kN unloading foce, 800rpm, 70bara suction pressure

- Application range:

- Majority of applications

- IP:

- Actuator: IP65

FPSU: IP65 - Actuator height / weight:

- 267mm / 20.5kg (NACE 23.5kg)

- EX-certificates*:

- ATEX Zone 1 IIC

- Power supply:

- Actuator: 60VDC

FPSU input: 3 x 400VAC - Electrical connections:

- Terminals

- Maintenance intervals:

- <400rpm: 32,000 operating hours

400 to 800rpm: 24,000 operating hours - Standardization:

- Same actuator for all stages / compressors

- Automatic clearance compensation:

- Yes

- Automatic wear compensation while compressor runs:

- Yes

- Separate enclosure required for FPSU / ePU:

- No

- *Status correct at the time of printing. Further approvals may already be available. Please contact us for details.

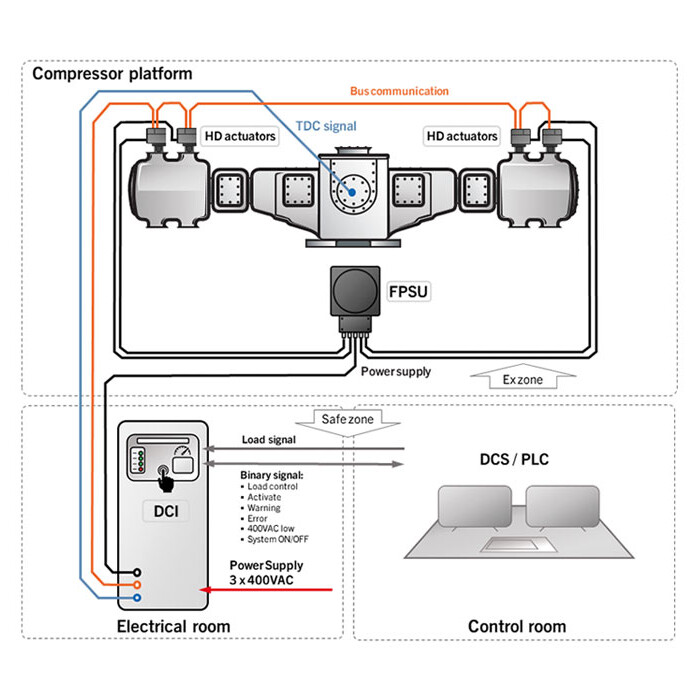

- Field Power Supply Unit (FPSU)

- Digital Compressor Interface (DCI)

- Top Dead Center (TDC sensor)

Electric Stepless Capacity Control System

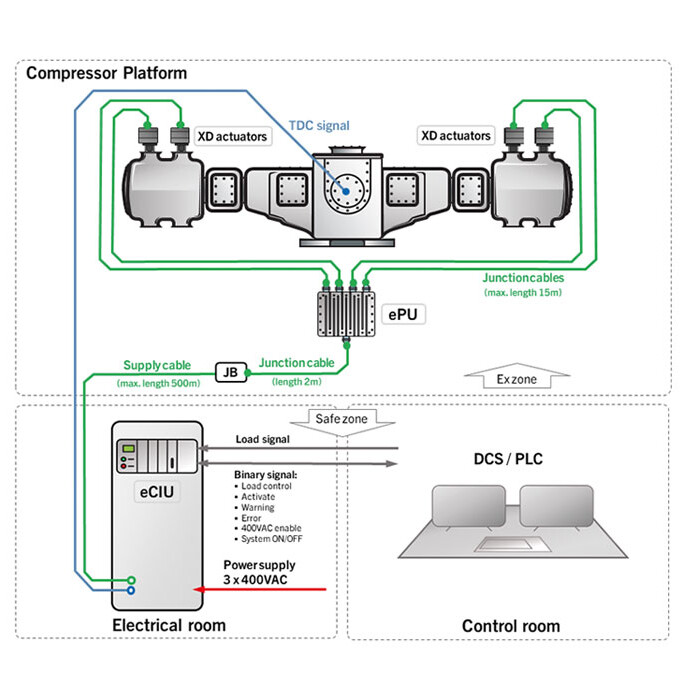

Xtreme Duty Double Stack Actuator

- Actuator layout:

- Dual magnetic coil stack

- Application limits:

- Up to 6.5kN unloading foce, 1,200rpm, 160bara suction pressure

- Application range:

- All HydroCOM applications incl. dia 17mm high force

- IP:

- Actuator: IP65

FPSU: IP67 - Actuator height / weight:

- 232mm / 20.0kg (NACE 23.0kg

- EX-certificates*:

- ATEX / IECx Zone 1 IIC, CSA C1/D2, TIIS, CCC

- Power supply:

- Actuator: 560VDC

ePU input: 3 x 400VAC - Electrical connections:

- Ex-connector

- Maintenance intervals:

- <400rpm: 32,000 operating hours

400 to 800rpm: 24,000 operating hours

800 to 1,200rpm: 16,000 operating hours - Standardization:

- Same actuator for all stages / compressors

- Automatic clearance compensation:

- Yes

- Automatic wear compensation while compressor runs:

- Yes

- Separate enclosure required for FPSU / ePU:

- No

- *Status correct at the time of printing. Further approvals may already be available. Please contact us for details.

- ePU: eHydroCOM Power Unit

- eCIU: Compressor Interface Unit

- TDC: Top Dead Center

- JB: Junction Box

Brochure A4

Brochure Letter Format

How can we help you?

Let us know if you need assistance or have questions – one of our compression representatives will contact you as soon as possible.

Don’t miss out on the latest news!

Sign up below to receive the latest news and updates from HOERBIGER about our compression products and services.